Optimize first, automate second: Three AI flaws to avoid

If your company is like most, you’re already injecting AI into your GTM processes, hoping for unprecedented gains in productivity. Will you get what you’re hoping for? According to a recent MIT report on AI, only 5% of AI pilots ever deliver P&L impact. It’s not that AI cannot deliver value; companies are deploying AI ineffectively and not focusing on process improvements before automating. Here’s what we know from using lean principles to optimize critical processes for nearly 100 ScaleUps: Automating a bad process amplifies inefficiency.

And if your automation du jour happens to be AI, that outcome can be exponential — warp-speed dysfunction.

This is the AI paradox: more automation, less value.

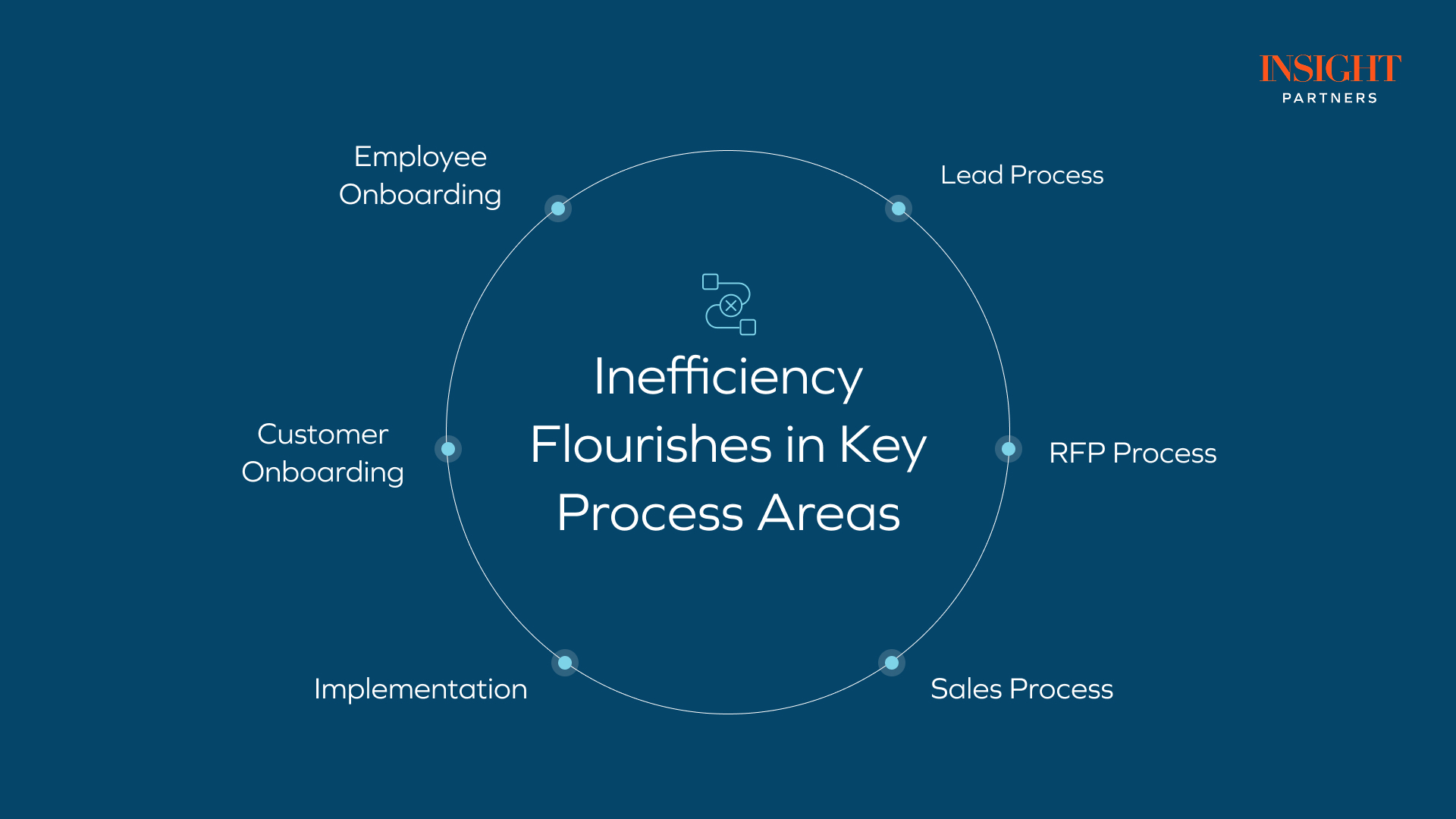

The temptation is to slap a shiny coat of AI on every complex workflow. 6Sense SVP Ann Neir confirms that, “There’s a wave of urgency right now: ‘We need AI for forecasting,’ ‘Let’s hyperautomate onboarding,’ and ‘Can we plug in copilots to support our GTM teams?’” The rush to automate is understandable, considering that over 20% of customer value and revenue can be lost annually due to inefficient processes.

However, despite the opportunity to automate these inefficient processes, the stats on successful automation aren’t wholly encouraging. Approximately 70% of automation initiatives fail to hit intended targets. Peter Drucker points out one reason why: “There is nothing so useless as doing with great efficiency that which should not be done at all.”

Behind these results are three primary errors — fatal flaws in a poor automation strategy.

Three fatal automation flaws

#1: The AI-first, business-second approach

Admittedly, AI can be dazzling, mesmerizing, even addictive. One senior GTM executive shared their disappointing attempt to use AI for outbound sales efforts, automating the initial research phase and crafting email messages to cold leads using prospect data. From the 5,000 emails sent over an entire quarter, not a single meeting was booked, due primarily to a lack of sufficient relevance to the receiver. Full automation, maximum efficiency, zero results.

This leader confessed to falling in love with the technology instead of focusing on the underlying business problem. In short, they bought a Formula 1 car when what they really needed was a special delivery van.

Consider it an early warning indicator if your team is so infatuated with the technology that the biggest questions sound like, “How can we use AI?” and “Which model should we choose?” instead of seeking to understand and align to customer-desired business outcomes.

#2: Automating suboptimized processes

Automating processes that are in themselves suboptimized is the core danger of the “AI-first” approach. By simply automating a wasteful process, you are not optimizing it; you are cementing its flaws and making them harder and more costly to correct later. You are building a digital infrastructure on a foundation of inefficiency.

The promise of AI is not just to do things faster, but to do them better — to uncover insights, predict outcomes, and personalize experiences in ways that were previously impossible. But AI’s ability to do so is entirely dependent on the quality of the process and the data it is given. When the process is flawed and you calcify it via automation, you leave AI’s potential untapped.

#3: Selling humans short

Further research from MIT suggests that employees frequently view automation as a real threat — not only to their skills and expertise but also to their autonomy and job security. These fears are real, and they can morph into resistance and potentially undermine behavior. Failure to address the human factor and provide paths for humans to succeed alongside automation can and has resulted in a cultural reaction that has doomed automation projects.

Fixing the flaws

The simple but disciplined path to fixing these three fatal automation flaws is to use a human-in-the-loop, process-first approach consistent with the time-tested principle of Lean, which is best thought of as the elimination of waste, or anything that blocks the flow of value to customers.

Insight’s Onsite advisors have spent years partnering with hundreds of companies on process automation and constant experimentation, leveraging the concept of human-centered automation born from the original Lean days at Toyota.

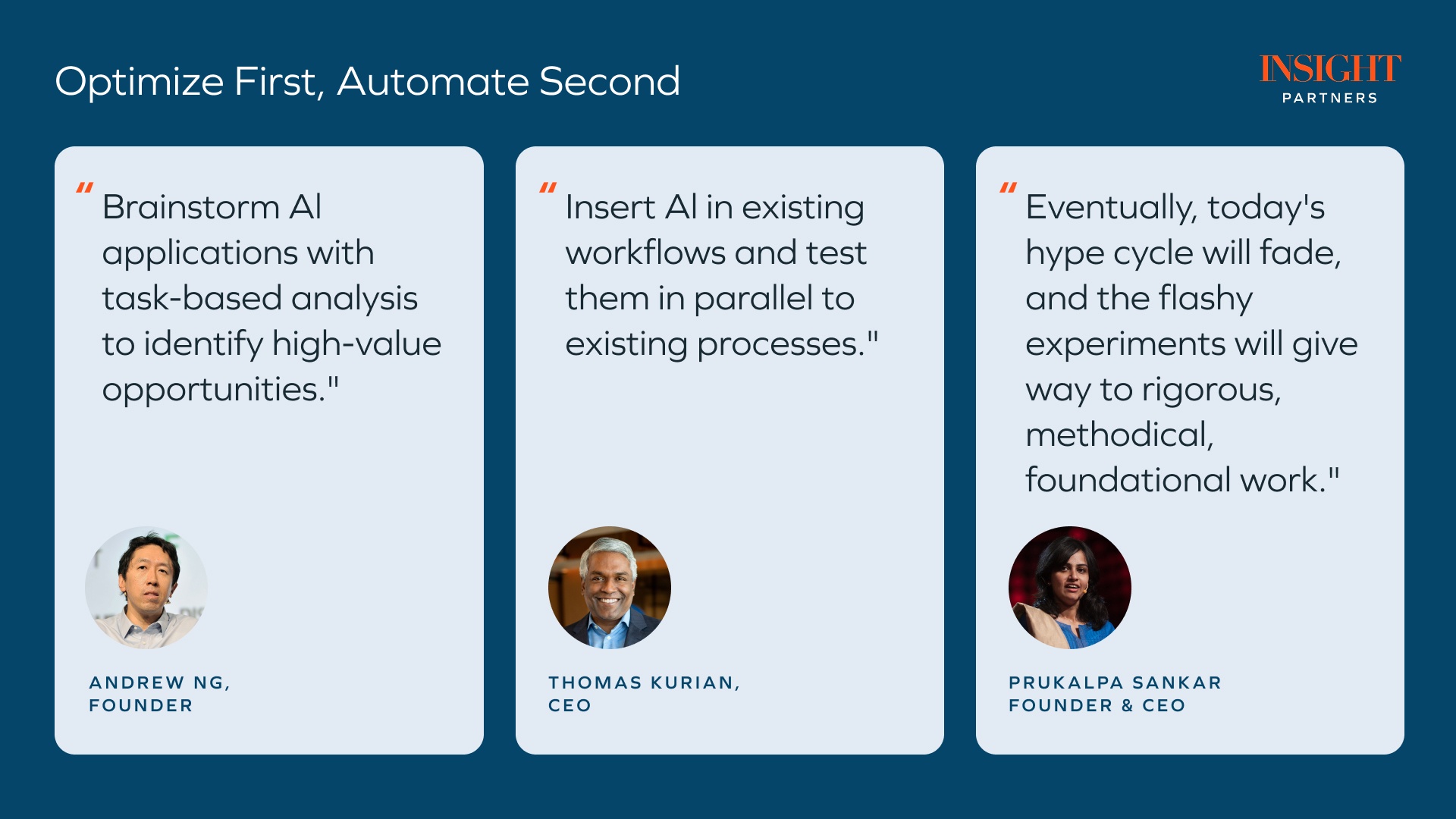

The Lean approach requires the discipline to pause the AI hype cycle and engage in the less glamorous but far more impactful hard work of manual process optimization. It means asking tough questions: Where are the bottlenecks? Where are the redundancies? Where is value truly being created, and where is it being delayed or even destroyed?

Start by aligning on a high-value business goal. Pick a stretch target, something north of a 20% improvement in a key metric: time to value, time to revenue, etc. Then employ these three steps with a cross-functional team:

Step 1: Map the “As-Is”

Every process has three versions:

- What you think it is

- What it actually is

- What it should be

In this step, focus on what the process actually is. Pinpoint the areas representing waste: redundancy, broken handoffs, errors, bottlenecks, delays, unnecessary motion — anything that a customer doesn’t care about, didn’t ask for, and wouldn’t pay for.

Step 2: Redesign it

Brainstorm optimal solutions, countermeasures, and ways to radically improve the process. Note opportunities to eventually automate certain steps.

Step 3: Run a rapid test

Run a simple, fast, and frugal test to validate the new way and standardize it to be repeatable.

As Section CEO Greg Shove advises, “… literally describe these workflows on paper, the inputs, the outputs, the dependencies, and the data required to make the workflow, to create the outcome or output. Whatever it is, human only. Describe it, then redesign it. See which ones AI can help with. Prioritize that list.”

The results

The gains from this simple, three-step technique often surprise those who execute it — 25% or better improvement in key processes and value metrics like lead-to-cash, time to value, and overall productivity — is par for the course. From a single workshop involving four small teams, one fintech company realized over 30% reduction in lead-to-revenue time, recaptured over $10 million of revenue at risk, and achieved 20% improvement in retention and productivity.

Once workflows are” leaned out” — once the waste has been identified and removed — the stage is set for a truly transformative AI implementation. With a clean, efficient process as its foundation, AI can begin to work its magic.

The optimize-first approach can deliver a powerful one-two punch:

- First, the initial process of eliminating waste can create immediate productivity gains and potential cost savings. The business becomes more efficient and effective even before the introduction of AI.

- Second, when AI is finally deployed, its impact is magnified. Instead of just automating a broken system, it is enhancing an already optimized one, thus further accelerating growth.

The pressure to adopt AI is immense, but the pressure to do it right should be even greater. The choice for senior leaders is clear: either take the seductive shortcut and risk automating your own dysfunction or take the more deliberate path of “leaning out” your processes first to gain the maximum benefits of AI.

Once you’ve done this correctly, you should be able to answer each of the following questions with a confident “yes”:

- Is eliminating waste in your key GTM processes a high priority?

- Are your key GTM processes optimized for efficiency and effectiveness?

- Do you have constantly updated standard operating procedures for all key processes?

With that foundation in place, automation is a friend, not an enemy. It can accelerate results, not dysfunction — delivering the results you designed and architected for — not just empty activity.

*Note: Insight has invested in Section and 6sense.