Behind the Investment: nTopology – Engineering Software Designed for Advanced Manufacturing

Computer Aided Design (CAD) software helps engineers design and manufacture physical items. It is a key component of digital transformation in manufacturing, and often allows companies to have a “digital twin” of their physical products to drive innovation. It is a multi-billion-dollar industry with a commoditized legacy product, with most incumbents focused on newer segments like the Internet of Things, or digital twins.

Many of these programs have been around for decades and are still running on the same 30-year-old physics technology built in the early 1990's. Technology such as boundary representation or a B-Rep kernel, were useful for representing shapes and designs as boundaries that together make up a 3D shape. This was well aligned with the traditional manufacturing processes of injection molding or CNC machining, given engineers have been confined to designing items with solid interiors and geometrically shaped exterior walls to be formed or cut around.

This all changed with the advent of additive manufacturing.

This new additive process, better known as 3D printing, has given rise to innovative physical manufacturing possibilities. Some examples used in production today include structural lightweighting of a dense part, a complex lattice and mesh pattern as an interior, organically shaping medical implants, or combining multiple bracket parts into one solid structure. Most of the popular CAD tools simply cannot handle the computational complexity needed to model the lattice patterns typically being 3D printed. Older B-Rep kernels are fundamentally incapable of modelling these types of structures consistently or efficiently, with small model changes taking days to render, often failing after all of that waiting. This was a rare case of a market where current hardware capabilities exceeded the level of sophistication of the software that accompanied it.

Enter nTopology, the next generation of advanced CAD software. We first met Brad Rothenberg in early 2019, before he had launched the nTop platform. We immediately saw a founder who lived and breathed all things CAD, hacking STL files since he was 10. He described a grand vision of building a CAD system from the ground up. Summarizing a lot of technical complexity, nTopology effectively created a new “implicit” kernel that represents complex geometry 10-100x faster than other B-Rep kernels by representing the math implicitly. Beyond just speed, this implicit kernel is more reliable as boundary conditions can never break when represented implicitly. Within the first few minutes of our meeting, Brad had his laptop out, rendering all sorts of complex designs from lightweighted rocket nozzles to latticed heatsinks in seconds. Seeing how quickly these designs were developed, it became clear to us they were building something special.

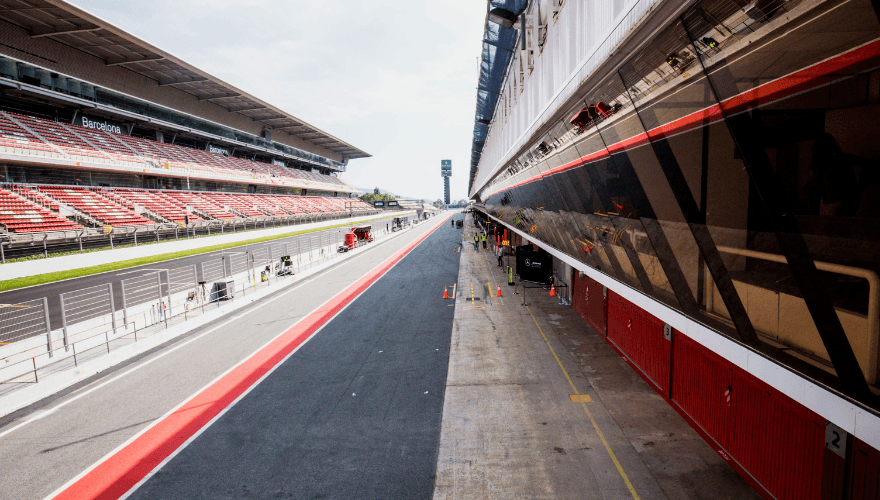

As we spent more time with Brad and the team over the year, we became even more impressed. We watched as they landed marquee customers in the auto, aerospace, and consumer products industries within a year of launching. In diligence, while spending time with their customers, we heard repeatedly that no other product on the market today had similar technology and capabilities. In today’s hyper competitive software ecosystem where every space has multiple players, we rarely hear this type of product feedback.

nTop’s platform today brings together the best of design, simulation, and advanced manufacturing. They’re enabling designs that were previously impossible, combining traditional CAD, implicit modelling, field driven design, and finite simulation, creating new geometries using generative design and topology optimization. They’re able to create specialized workflows that could automate huge amounts of work for large teams. Doing all of this in a program that is computationally efficient where it can run on any standard laptop workstation, is nothing short of a generational leap forward in CAD technology. We’re excited to be a part of their ScaleUp journey, leading their latest fundraise, and if you’re an engineer interested in using their platform, check them out online.