Break Through with These 5 Lean Principles from Unicorn Companies

In 1988, John Krafcik coined the term “lean” in his graduate work at MIT’s International Motor Vehicle Program. His paper, “Triumph of the Lean Production System,” challenged that it was not the location, the culture, or even the technology that determined car manufacturing plant performance. Indeed, the plants that operated with a “lean” production mindset were highly productive, while maintaining high quality. Lean was his way to express what he came to believe in his previous role as a Toyota manufacturing engineer to be the essence of the game-changing Toyota Production System: “an absence of slack in the system, aka waste.” Krafcik famously went on to become CEO of Waymo, the self-driving car company spinout of Google’s parent company, Alphabet.

Watch: What a Unicorn Knows: 5 Principles for Growth in 2023

A key part of Insight Partners’ approach to helping portfolio companies scale has centered on helping leaders eliminate these kinds of organizational impediments, applying the principles of lean thinking in a rather unconventional way: to the operations of software ScaleUps. That work with highly successful “unicorn” companies has led to the development of five foundational principles any company can use to create rapid and lasting growth.

Five lean ScaleUp principles

The term “lean” became popularized as a management philosophy with the 1996 bestseller Lean Thinking by James Womack and Daniel Jones, who led the MIT study during John Krafcik’s graduate work in the late 80s. In 2011, lean gained a resurgence in the tech world with Eric Ries’ The Lean Startup, which focused on helping entrepreneurs test ideas and iterate quickly.

Over the years, lean has evolved and grown to become an organizing principle that engages people in adding the highest possible value for customers across all operations. What makes lean compelling and different as a management philosophy is how that value is created. The lean process is one of addition by subtraction — reducing or removing anything that impedes the free flow of customer-defined value. Amazon calls it “working backwards.”

We have discovered that applying a broader interpretation of lean can be a powerful stance for battling the momentum-stealing effects of drag, inertia, friction, and waste. By keeping Krafcik’s original idea of “zero slack” front and center in efforts to help tech firms scale for growth, we have seen certain themes repeat themselves across various successful scaling companies. Those patterns evolved into a set of guiding principles, which, when adopted, make success more likely. The handy mnemonic to remember is SCALE:

- Strategic Speed

- Constant Experimentation

- Accelerated Value

- Lean Process

- Espirit de Corps

Learn more about using these lean principles for rapid, lasting growth. What a Unicorn Knows is out now!

Principle 1: Strategic Speed

Fighter pilots, professional cyclists, and race car drivers know what geese flying in a V formation know: You can travel faster and farther with half the effort by “drafting” in the slipstreams created by those in front of you. The faster you go, the more energy you save. It’s a virtuous cycle. And the more people in alignment, the bigger the slipstream, so you go even faster. This is the simple physics of momentum, the equation for which is velocity (speed with direction) times mass.

You can apply the concept to your company’s strategies. We call it strategic speed, defined as the optimal speed for swift strategy deployment and decision-making.

To produce a similar effect and create the organizational equivalent of slipstreams requires strategies, priorities, and objectives to be simultaneously linked vertically and horizontally. Mechanisms like Japan’s Hoshin Kanri (“strategy deployment” or “policy management”) and the younger but more well-known Western version, OKRs (objectives and key results), implemented with tools and practices like the lean alignment practice of catchball — essentially the business equivalent of the children’s game of tossing a ball back and forth — help boost strategic speed.

We have observed that ScaleUps achieving company-wide alignment are able to accelerate their growth over 30% more than their peers.

Principle 2: Constant Experimentation

Continuous innovation is a survival need and a competitive must. Without that capability, inertia will act as a speed governor. But innovation cannot be relegated to department status or reserved for the next-level killer app that may never materialize. Doing so is an inertia-producing temptation, but one that can be avoided by making simple, fast, and frugal experimentation an operating norm.

One of the big misperceptions about lean is that it’s all about quality and cost. Those who have spent time embedded in the Toyota culture will delight in correcting you, letting you in on the little-known fact that the Toyota Production System was developed to shorten the time from order to delivery and create a “dash to cash” method without requiring the deep resources of the big U.S. automotive companies. The entire system was evolved through a series of desperate experiments to scale up and grow revenue faster with less.

For high-velocity ScaleUps, creating a steady stream of innovative new product and process concepts that consistently make it to market requires an equally fast, lightweight, high-impact method for carrying out constant experimentation, one that is, unfortunately, missing in most.

Experimentation also isn’t just about product development. Applying agile principles to rolling out a new sales process in one market allows you to test and improve before rolling out globally to your entire organization. As Netflix’s co-founder and first CEO Marc Randolph writes in his 2019 book, That Will Never Work:

“I’ve realized that the key to being successful is not how good your ideas are, it’s how good you are at being able to find quick, cheap, and easy ways to try your ideas.”

Principle 3: Accelerated Value

A failure to understand and align with customers on their desired business outcomes can produce enough downstream friction to produce what every recurring revenue business dreads: churn.

The tendency is to equate the concept of a customer journey with a sales funnel coupled with a monolithic view of the customer, which is wrong. In other words, customer = account is a key source of friction that can ultimately lead to head-scratching when seemingly satisfied customers churn.

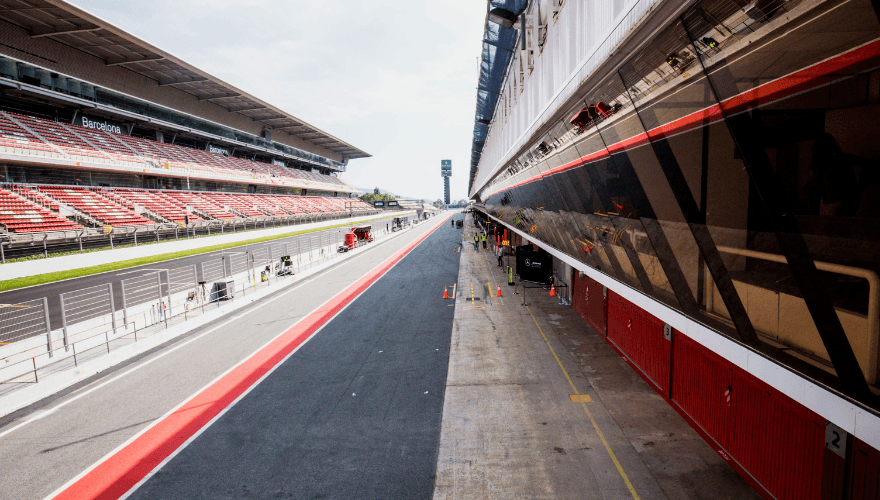

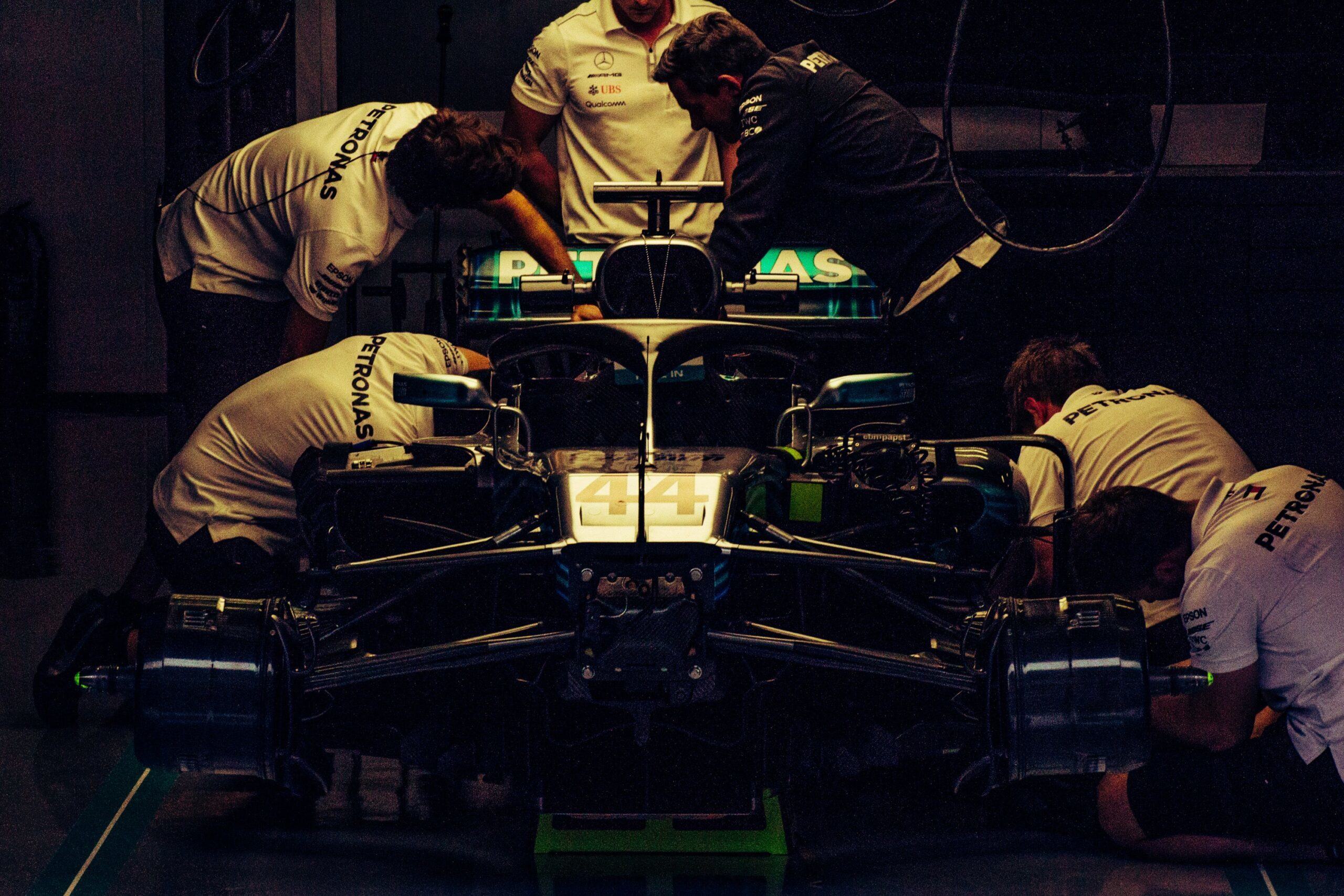

At the root of the issue is the difficulty of thinking and operating horizontally in a structurally vertical world. Customers are organized vertically, as are most company support functions, but the customer experience is horizontal. Rather than think like a star quarterback leading a team with set plays being sent in from the sideline (vertical thinking), think like a Formula One pit crew. A horizontally-oriented Formula One team has over 20 people with specific roles so tightly synchronized that they can stabilize the car, change the tires, adjust the aerodynamics, and safely release the car to get back in the race in under two seconds.

Enabling customers to realize value quickly promotes product adoption and positively impacts community spread, customer retention, renewal, and expansion. Ensuring that everyone in your company is aware of how to enable that value quickly, and in a unified fashion, only helps to accelerate your growth through improved customer satisfaction.

Principle 4: Lean Process

Lean as a concept encourages simplicity as the path to speed. It holds that less is best, and that to make more room for what truly matters, eliminate what doesn’t. It’s a subtractive approach to continuously improving and simplifying even the most complicated workflows. It starts with a clearly defined value, then systematically removing everything blocking the path to delivering it. It’s a relentless endeavor, a different way of thinking, and requires a mind shift.

Targeting waste involves using a methodology over 80 years old developed by the U.S. War Department in 1940, who coined the term continuous improvement. The concept was aimed at the effort to convert the American manufacturing base to the war effort. It was then utilized to stabilize war-torn Japan under the leadership of General Douglas MacArthur during the seven-year U.S. occupation. Japan, having scarce resources other than human creative capital, termed it kaizen, meaning “change for better.”

With fast-moving tech ScaleUps, we use an adapted method of traditional continuous improvement called a kaizen blitz, which works best, as it is both faster and more effective.

When applying lean principles within Insight’s portfolio companies, we have been able to achieve a 20-30% improvement in time to value.

Principle 5: Espirit de Corps

You can’t build a Formula One car by yourself, or for that matter, a company. It takes a team and leaders of and within that team to create the kind of environment that enables the first four principles to come to life.

Enter the notion of esprit de corps. French for “group spirit,” esprit de corps figures centrally in military and paramilitary organizations, which are notorious for favoring results-oriented leadership. “Mission first, people always” is the mantra. But social research suggests that for a high-velocity organization like a ScaleUp, a cohesive culture of “people first, mission always” may just be a better approach.

As UCLA social psychologist Matthew Lieberman reveals in his bestselling book, Social: Why Our Brains are Wired to Connect, those viewed as having predominantly strong results focus have only a one-in-seven chance of being viewed as a great leader, while those viewed as having a predominantly social or empathic focus have about the same or slightly less chance. But for those strong in both results and social skills, the likelihood of being seen as a great leader is five times greater.

Leaders of this ilk understand that a people/culture fit is every bit as important as a product/market fit when it comes to scaling for growth. Your star product requires a team of star players to advance it to market and capture maximum value…so much so that Netflix is happy to advertise to all job seekers that they will pay an ill-fitting employee an industry-leading severance of four months’ pay while they search for a star replacement.

What a unicorn knows

A cursory glance at each of the individual principles in the S.C.A.L.E. framework might lead you to ask whether there is anything really new here. That’s fair. What is unique is the lean interpretation of the principle: Well-worn terms like strategy and experimentation take on entirely new meanings when viewed through the lens of lean. What is unique is the synergy created from integrating any one of the individual principles with the other four and pointing the collective model toward the goal of scaling up by leveraging a lean, zero-slack mindset.

Learn more about applying lean principles to scale by reading our book, out now: What A Unicorn Knows.